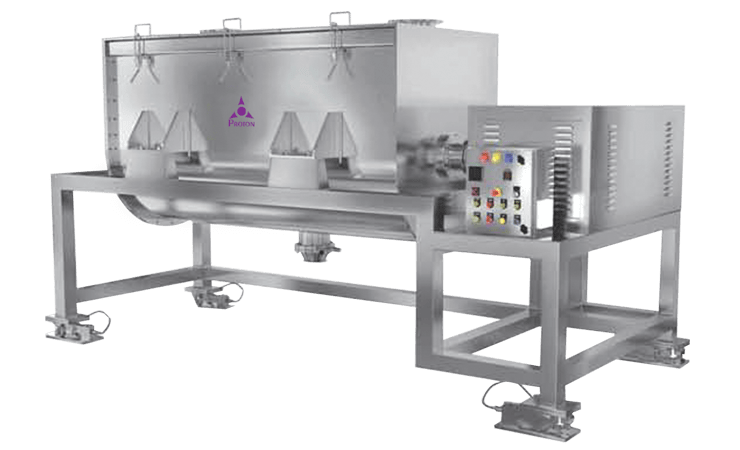

Ribbon Blender Machines

A ribbon blender machine is a type of industrial mixing equipment used for blending dry powders, granules, and other solid materials. The machine consists of a U-shaped trough or vessel with a rotating agitator consisting of inner and outer helical ribbons. The outer ribbon moves the material in one direction while the inner ribbon moves it in the opposite direction, ensuring that the material is well mixed.

The ribbon blender machine is commonly used in various industries such as food, pharmaceuticals, chemicals, and cosmetics for mixing dry ingredients such as powders, granules, and other solid materials. The machine is designed to handle a wide range of materials and can be used for both gentle and intensive mixing. The blending process is relatively quick and efficient, and the machine is easy to operate and clean.

Some of the advantages of using a ribbon blender machine include:

- Uniform mixing: The ribbon blender machine ensures that the material is well mixed, resulting in a uniform blend.

- Versatility: The machine can handle a wide range of materials, making it a versatile piece of equipment.

- Efficiency: The ribbon blender machine is designed for quick and efficient mixing, reducing the processing time.

- Easy to clean: The machine is easy to clean, minimizing the risk of cross-contamination.

- Low maintenance: The machine is relatively simple in design and requires minimal maintenance.

The ribbon blender machine is a reliable and efficient piece of equipment that is widely used in various industries for blending dry materials.

Salient Features: Ribbon Blender Machines

- Available in standard cGMP and customized models with SS 304/316/316L contact parts

- The container shape and the mixing stirrer gives continuos movement resulting in better quality mixing and blending

- Ribbons are designed in such a way so as to provide both radial and linear motion for a complete homogenous mixing

- Provided with dust proof top cover with window

- Various types of ribbon blenders such as pressure, double spiral etc are available

- Modern PLC with manual operating system

- Available in batch capacities ranging from 50 Kgs to 5,000 Kgs, as per client’s requirements, depend on Bulk Density

Frequently Asked Questions

A: A tablet press machine, also known as a tablet compression machine, is used to compress powder into tablets of uniform size, shape, and weight, commonly used in pharmaceutical, nutraceutical, and other industries.

A: Regular maintenance includes cleaning the machine after each use, lubricating moving parts, inspecting dies and punches for wear, and conducting periodic calibration to ensure accurate tablet production.

A: There are two main types of tablet press machines: single-station (single punch) and multi-station (rotary) presses. Single-station presses are used for small-scale production, while rotary presses are designed for high-volume manufacturing.

A: Consider factors such as production capacity, tablet size and shape requirements, material properties, ease of operation, and budget. Consulting with a manufacturer or supplier can also help you select the most suitable machine for your specific application.

Yes, we offer comprehensive training programs for operators and maintenance staff, as well as ongoing technical support to help you maximize your machine’s efficiency and productivity.

Absolutely. We can customize our tablet press machines to meet specific requirements, including unique tablet shapes, sizes, and formulations. Contact us to discuss your customization needs.

Request a call back

For Business: Do you have questions about how Proton Engineers can help your company? Send us an email sales@protonengineers.com and we’ll get in touch shortly, or phone +91 89055 34795 — we would be delighted to speak.