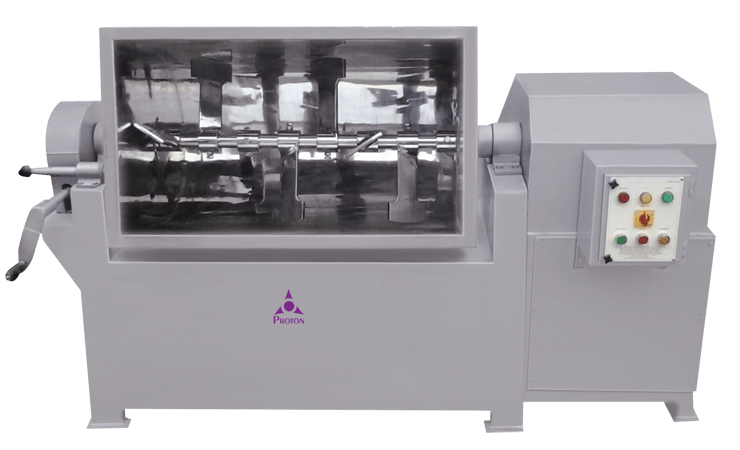

Mass Mixer Machines

A mass mixer machine is a highly efficient industrial mixing equipment that is designed to mix a large quantity of materials at once. These machines are widely used in various industries, including pharmaceuticals, chemicals, food, and cosmetics.

Typically, a mass mixer machine comprises a cylindrical drum or a U-shaped trough with a horizontal axis. The drum or trough is equipped with mixing blades or paddles that rotate around the central axis to ensure thorough mixing of the materials.

The process of mixing involves loading the materials into the drum and starting the machine. The mixing blades or paddles rotate, and the materials are mixed uniformly. The duration of the mixing process varies depending on the quantity and nature of the materials being mixed, ranging from a few minutes to several hours.

Mass mixer machine is ideal for mixing dry powders, granules, and other solid materials. It can also be used for mixing wet materials, such as pastes and creams.

One of the key advantages of using a mass mixer machine is its ability to provide efficient and consistent mixing, which results in improved product quality. Additionally, these machines help reduce labor costs and are easy to operate and maintain, making them a popular choice for many industries.

Mass mixer machine is an essential piece of equipment for industries that require large-scale mixing of materials. Its ability to provide efficient and consistent mixing, reduce labor costs, and improve product quality makes it a valuable investment for any business.

Salient Features: Mass Mixer Machines

- Design is cGMP – Current Good Manufacturing Practices compliance

- All contact parts AISI 316 & non contact parts AISI 304

- Uniform Mixing with paddle blade stirrer

- Self adjusting sealing arrangement to avoid entire black particles

- Tilting device for easy unloading and cleaning

- The interlocked acrylic covers of product container, enclosed drive & Overloads relay protection

Frequently Asked Questions

A: A tablet press machine, also known as a tablet compression machine, is used to compress powder into tablets of uniform size, shape, and weight, commonly used in pharmaceutical, nutraceutical, and other industries.

A: Regular maintenance includes cleaning the machine after each use, lubricating moving parts, inspecting dies and punches for wear, and conducting periodic calibration to ensure accurate tablet production.

A: There are two main types of tablet press machines: single-station (single punch) and multi-station (rotary) presses. Single-station presses are used for small-scale production, while rotary presses are designed for high-volume manufacturing.

A: Consider factors such as production capacity, tablet size and shape requirements, material properties, ease of operation, and budget. Consulting with a manufacturer or supplier can also help you select the most suitable machine for your specific application.

Yes, we offer comprehensive training programs for operators and maintenance staff, as well as ongoing technical support to help you maximize your machine’s efficiency and productivity.

Absolutely. We can customize our tablet press machines to meet specific requirements, including unique tablet shapes, sizes, and formulations. Contact us to discuss your customization needs.

Request a call back

For Business: Do you have questions about how Proton Engineers can help your company? Send us an email sales@protonengineers.com and we’ll get in touch shortly, or phone +91 89055 34795 — we would be delighted to speak.