We Offer The Most Complete Product Innovation In The building Installations Market

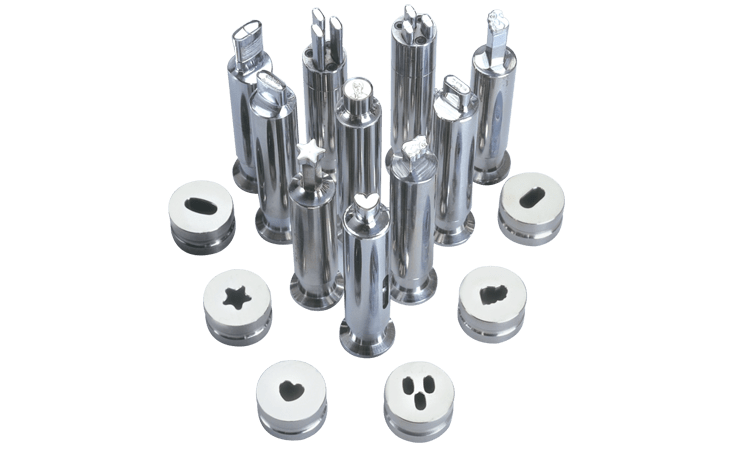

We design and manufacture some of the best quality dies & punches for our buyers. Our dies and punches are crafted from the best quality hchc and ohns(t) material. Our experts can also offer dies & punches that are produced by using premium-grade steel s7 in case our clients have a special requirement. Apart from that we also work on hard chrome plating as well as chrome nitriding on the upper punches according to client demand. Being a leading manufacturer of different types of dies and punches, we maintain the highest levels of quality with all the products that we offer.

We design and manufacture dies and punches in numerous shapes as well as under in b tooling, d tooling, bb tooling, hollow tablet tooling, veterinary tablet tooling, and also any special kind of tooling based on client demand. Some of the dies and punches products that we have at our disposal include round shape, capsule shape, oval shape, and odd shape products. So do not hesitate to get in touch with us to learn more about our dies & punches.

| Model | Proton DE-150 |

|---|---|

| Suction Capacity | Maria Anders |

| Inlet Connection | Francisco Chang |

| Electricals Motor | Roland Mendel |

| Overall Dimensions | Helen Bennett |

| Case Dimensions | Yoshi Tannamuri |

| Net Weight (Kgs.) | Giovanni Rovelli |

| Gross Weight (Kgs.) | Giovanni Rovelli |

*Specifications are subjected to change without notice.

Frequently Asked Questions

A: A tablet press machine, also known as a tablet compression machine, is used to compress powder into tablets of uniform size, shape, and weight, commonly used in pharmaceutical, nutraceutical, and other industries.

A: Regular maintenance includes cleaning the machine after each use, lubricating moving parts, inspecting dies and punches for wear, and conducting periodic calibration to ensure accurate tablet production.

A: There are two main types of tablet press machines: single-station (single punch) and multi-station (rotary) presses. Single-station presses are used for small-scale production, while rotary presses are designed for high-volume manufacturing.

A: Consider factors such as production capacity, tablet size and shape requirements, material properties, ease of operation, and budget. Consulting with a manufacturer or supplier can also help you select the most suitable machine for your specific application.

Yes, we offer comprehensive training programs for operators and maintenance staff, as well as ongoing technical support to help you maximize your machine’s efficiency and productivity.

Absolutely. We can customize our tablet press machines to meet specific requirements, including unique tablet shapes, sizes, and formulations. Contact us to discuss your customization needs.

Request a call back

For Business: Do you have questions about how Proton Engineers can help your company? Send us an email sales@protonengineers.com and we’ll get in touch shortly, or phone +91 89055 34795 — we would be delighted to speak.