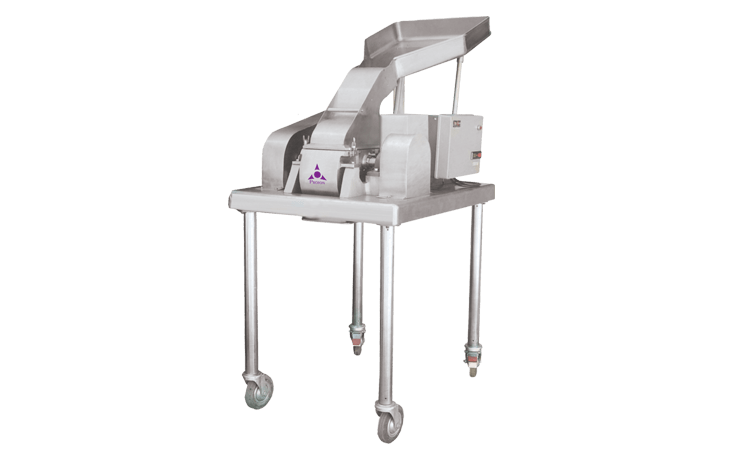

Comminuting Mill Machines

A comminuting mill is a highly effective machine utilized for reducing the particle size of solid materials. This process is achieved by applying force to the material, causing it to break apart into smaller pieces. Typically, the machine consists of a rotating blade or rotor that crushes or grinds the material. The blade or rotor may be equipped with sharp edges, blunt edges, or a combination of both.

Comminuting mill machines are widely used in the pharmaceutical, food processing, and chemical industries to reduce the size of particles for various applications. Some common examples of materials that may be processed with a comminuting mill include tablets, sugar, spices, and pigments.

There are several different types of comminuting mill machines, including hammer mills, pin mills, and ball mills. Each type of mill has its own specific features and capabilities, and the choice of machine will depend on the specific needs of the application.

Pharma Comminuting Mill Machine

| Model | Proton / CM |

|---|---|

| Output (Kg/Hr)* | 25 to 300 |

| Rotor speeds (RPM) | 1000 – 2250 – 4500 |

| Rotor Blades | Swinging type with knife and impact edge |

| Screens | (1) Round hole perforated Stainless steel sheet (2) Woven stainless steel wire mesh |

| Main Electric Motor (Kw/Hp | 5.50 / 7.50 |

| Electrics | (a) 415V / 3 Phase / 50 Hz |

| Overall Dimensions L x W x H (mm) | 1260 x 690 x 1700 |

| Net weight (Kgs.) | 310 |

*Specifications are subjected to change without notice.

Comminuting mill machines are an essential tool for particle size reduction in many different industries. They are widely used due to their versatility, efficiency, and reliability. The ability to reduce particle size is crucial in many applications, and comminuting mills provide a highly effective solution.

Salient Features: Comminuting Mill Machine

- Versatile machine for particle size reduction and operation

- Beaters assembly is in a separate pillow blocks for ease in maintenance Very less down time, as only beaters assembly will have to be reversed (and not the complete chamber) for making it knife to impact forward or vice-versa which can be done by operator

- Swing type beaters assembly is provided as a standard supply which increases the output by 10 to 30% and is easy to clean

- Water jackted chamber is also available of demand

- Beaters are made from HCHC material with hard chrome plating

- Beaters assembly is dynamically balanced which reduces vibration and noise level and increases bearing life

- Castors are provided for mobility and brakes can be applied for fixing machine at one place

- Flame proof electrical can be provided on demand at extra cost

Frequently Asked Questions

A: A tablet press machine, also known as a tablet compression machine, is used to compress powder into tablets of uniform size, shape, and weight, commonly used in pharmaceutical, nutraceutical, and other industries.

A: Regular maintenance includes cleaning the machine after each use, lubricating moving parts, inspecting dies and punches for wear, and conducting periodic calibration to ensure accurate tablet production.

A: There are two main types of tablet press machines: single-station (single punch) and multi-station (rotary) presses. Single-station presses are used for small-scale production, while rotary presses are designed for high-volume manufacturing.

A: Consider factors such as production capacity, tablet size and shape requirements, material properties, ease of operation, and budget. Consulting with a manufacturer or supplier can also help you select the most suitable machine for your specific application.

Yes, we offer comprehensive training programs for operators and maintenance staff, as well as ongoing technical support to help you maximize your machine’s efficiency and productivity.

Absolutely. We can customize our tablet press machines to meet specific requirements, including unique tablet shapes, sizes, and formulations. Contact us to discuss your customization needs.

Request a call back

For Business: Do you have questions about how Proton Engineers can help your company? Send us an email sales@protonengineers.com and we’ll get in touch shortly, or phone +91 89055 34795 — we would be delighted to speak.