An elevating de-dusting machine can be called one of the most powerful members of this particular fraternity. These machines are known for their high extent of efficiency and that too across a wide spectrum of applications.

Some Important Information on Mini Tablet Press Machines

The mini tablet press machines are available in a wide range of models. The best among them are the ones that are built as per the Table Top Square GMP model.

The Different Kinds of Pharma Ancillary Machines

When it comes to pharma ancillary machines the first name that comes to mind is that of the tablet coating machines. The best machines in this respect are ones that have a sturdy structure.

Working & Types of Tablet Coating Machines

The tablets have a thin coating on the outer surface either to give colour or to change the taste of the tablet. To apply this coating, we use the tablet coating machine. There are many kinds of coating machines.

The necessity for the coating of the tablets:

The other reasons for the coating of the tablet using the Tablet Coating Machines are these:

- Release the drug in controlled amounts.

- Protect the tablet from external impact or chemical contamination.

- Include chemicals in the coating that help modify the action of the tablet.

- Make the tablet appear attractive.

- Prevent the disintegration of the tablet once it reaches the stomach.

Tablet coating machines work on the simple action of spraying the coating material on the tablets as they rotate in an orbital manner.

Structure of the coating pan:

The standard coating pan is 15 – 200 cm in diameter. It remains tilted on a benchtop stand. An electric motor is used to keep the bench in motion. The batch of tablets to be coated is loaded onto the tray where they keep tumbling within the pan. Atomised form of the coating solution is applied continuously on the rotating tablets and so we can achieve an even coating on the tablets.

There are angled baffles on the drum and a current of air is directed onto the tablets to make the coating dry fast.The the efficiency of drying is obtained by use of these:

- Diffuser and baffled pan.

- Immersion sword.

- Immersion tube system.

The perforated pan is an essential item. This pan rotates on a horizontal axis and remains protected in a sealed housing. There are many types of which Driacoater, Glatt coater, and Accela-cota systems are the most popular.

Working of the Driacoater:

In the Driacoater Tablet Coating Machines, the drying air is installed inside the outer wall of the rotating pan. Channels of supply and exhaust air get directed to a hollow area as needed. The dip gets introduced into the tablet as the drum rotates while the dry air passes through. This fluidizes the tablet bed and the exhaust air is sent out through the back of the pan. In the Accela-cota system, drying air is shown to the drum and then released through the holes in the drum.

Working of the Glatt coater:

In the Glatt coater, the drum is fully perforated to maximise the spray traits. The process time is extremely small. The process of horizontal airflow reduces the nozzle region turbulence and increases the coating efficiency. In the next type, the fluidized bed system, a vertical cylinder is the chamber. The cylinder has a column of air flowing from the bottom centre and this creates the fluidization of the pellets.

The core of the tablet is susceptible to disintegration and so care must be shown when we coat the tablets. The tablets in the centre move upwards and fall upwards and downwards in the direction of the chamber wall. It again enters the air stream in the bottom part of the cylinder. Spray nozzles kept at the top and bottom of the cylinder help to coat the talents as they enter or leave the spray stream.

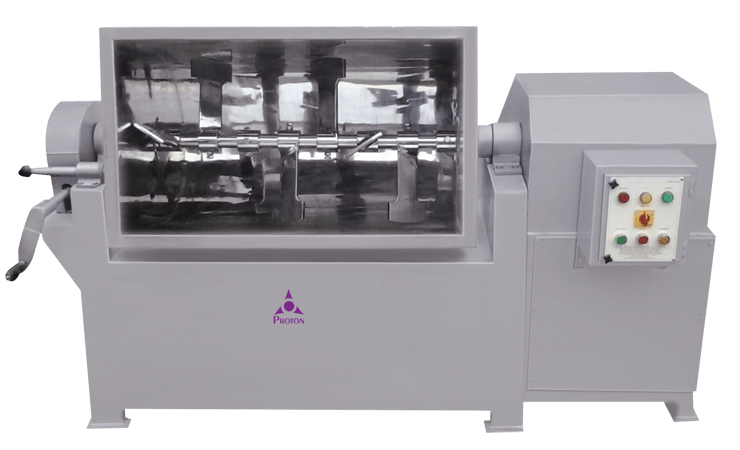

Design Structure & Working of the Octagonal Blender

The octagonal blender is used for mixing granular products. You can also use it for blending and lubrication of pharmaceutical products, chemicals and cosmetics.

Parts & Working of the Granulator and Tableting Machine

The rotary compression machine is widely used to make tablets for the pharmaceutical industry. We have many kinds of machines but they all work on the same principle.

Structure & Operations of Tablet Making Machines

Use of automation in the pharmaceutical machines has brought a good advancement in the way we handle and packaged medicines.

Uses & Types of Pharma Machinery

The pharma industry has a wide range of needs by way of machinery and equipment. This includes but is not limited to Tablet Coating Pan, Tablet Compression Machine,

Types & Structure of Dry Granulation Machines

When we don’t use any liquid to make granules, we call the process dry granulation. This is possible by applying pressure for densification and agglomeration of dry powder.

Uses & Parts of a Tablet Press

We use a tablet press to compress powder into tablets that are uniform in size, weight, and shape. These tablets find use in the pharmaceutical, cosmetics, and cleaning industry.