Elevating Dedusting Machines

An elevating dedusting machine is a vital piece of equipment utilized in industrial settings to eliminate dust, debris, and other harmful contaminants from the air. This machine typically comprises a series of filters or collection chambers, a blower or fan, and a conveyor or elevating system that moves the collected material to a disposal area.

The elevating feature of this machine allows it to be positioned at a height that enables efficient collection of airborne particles. The collected particles are then transported by the conveyor or elevating system to a collection bin or disposal area.

Elevating dedusting machine is widely used in industries such as mining, woodworking, metalworking, and construction to mitigate the risk of respiratory issues for workers and to comply with environmental regulations. They are also utilized in the food and pharmaceutical industries to maintain hygiene standards and prevent contamination.

When selecting an elevating dedusting machine, it is crucial to consider factors such as the type of dust or debris to be collected, the required airflow capacity, and the size of the area to be cleaned. Regular maintenance and filter replacement are also essential to ensure optimal performance and prevent equipment failure.

An elevating dedusting machine is a valuable investment for any industrial setting that prioritizes the health and safety of its workers and the environment. By effectively removing harmful particles from the air, this machine helps to maintain a clean and healthy work environment while also complying with regulatory standards.

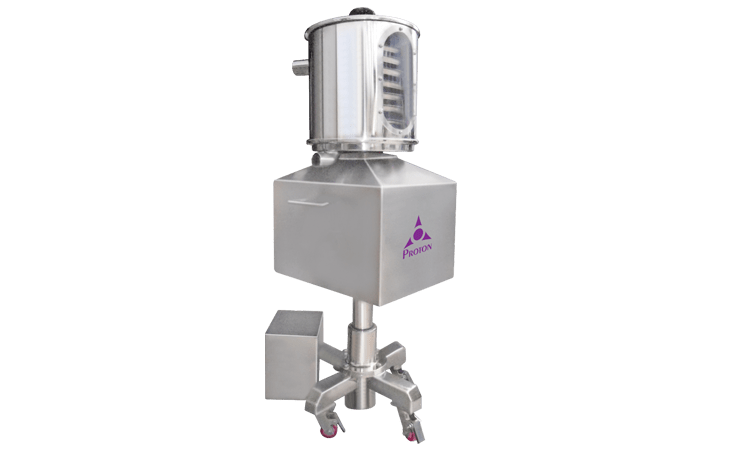

Buy the Elevating Dedusting Machine from one of the top manufacturers & suppliers of ancillary machines. Our products are designed to produce simple as well as precise results in the pharmaceutical, food, and chemical industries. Trust in our expertise to provide you with the highest quality pharmaceutical machines for your business needs.

Pharma Elevating Dedusting Machines

| Model | Proton ED-300 |

|---|---|

| Output (for 8 mm Tablet) | 5,000 to 3,50,000 tablet / Hr. |

| Max. De-dusting Route | 6 |

| Max. Up Movement | 460 mm |

| Power Supply | 220 V / 50 Hz. / 1 Phase |

*Specifications are subjected to change without notice.

Frequently Asked Questions

A: A tablet press machine, also known as a tablet compression machine, is used to compress powder into tablets of uniform size, shape, and weight, commonly used in pharmaceutical, nutraceutical, and other industries.

A: Regular maintenance includes cleaning the machine after each use, lubricating moving parts, inspecting dies and punches for wear, and conducting periodic calibration to ensure accurate tablet production.

A: There are two main types of tablet press machines: single-station (single punch) and multi-station (rotary) presses. Single-station presses are used for small-scale production, while rotary presses are designed for high-volume manufacturing.

A: Consider factors such as production capacity, tablet size and shape requirements, material properties, ease of operation, and budget. Consulting with a manufacturer or supplier can also help you select the most suitable machine for your specific application.

Yes, we offer comprehensive training programs for operators and maintenance staff, as well as ongoing technical support to help you maximize your machine’s efficiency and productivity.

Absolutely. We can customize our tablet press machines to meet specific requirements, including unique tablet shapes, sizes, and formulations. Contact us to discuss your customization needs.

Request a call back

For Business: Do you have questions about how Proton Engineers can help your company? Send us an email sales@protonengineers.com and we’ll get in touch shortly, or phone +91 89055 34795 — we would be delighted to speak.